CANDIED FRUIT LINES

Candying consists of replacing the water in fruit with sugar.

The process is based on osmosis – dipping the fruit in sugar syrup – and takes a long time when done in open tanks.

To streamline the osmosis process, it has to be made under vacuum: while the product is absorbing the sugar from the syrup, sugar syrup concentration is reduced and in order to get it back some of the water in the product needs to be evaporated.

A dissolver is used to prepare the syrup.

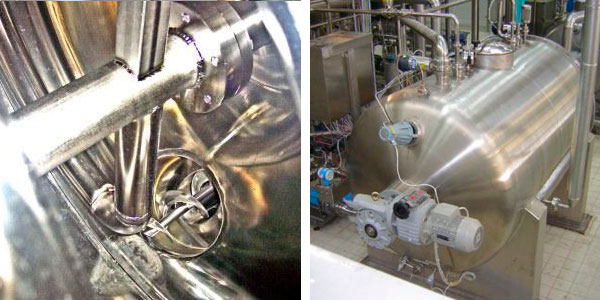

We manufacture two types of candying machines: the vertical type with perforated baskets (the fruit is loaded in baskets) and the horizontal type where the fruit is loose.

The product is loaded into the candying machines with glucose which is topped up as it evaporates.

When the process is completed, the glucose is unloaded first and stored for another candying process; the candied fruit is hold in tanks and filling later on.

Once the product is filled, the containers are pasteurised inside a tunnel.

Italiano

Italiano Français

Français Español

Español Русский

Русский Português

Português